hardness test reference|hardness test meaning : discounter The Rockwell hardness test method, as defined in ASTM E-18, is the most . Baixe o League of Legends e escolha seu Campeão entre mais de 140 opções. Jogue modos de jogo variados, como Summoner's Rift, ARAM e Teamfight Tactics, e fique por .

{plog:ftitle_list}

Resultado da 29 de set. de 2023 · Uma das pessoas que tiveram prejuízos com a plataforma é a maquiadora Jhenifer Blume, que mora em São Luís. Ela .

Listed below are common American Society for Testing and Materials (ASTM) standards that reference hardness testing. Newage Testing Instruments recommends that you obtain a copy of the appropriate standard for your application and that you read and .

Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of .

The Rockwell hardness test method, as defined in ASTM E-18, is the most .Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .achieved with Buehler’s test blocks. Wilson Hardness Reference Blocks are certified according to ASTM E18, ASTM E10, ASTM E92, ISO 6506-3, ISO 6507-3, ISO 6508-3, ISO 4545-3, JIS B 7730, JIS B 7735, JIS B 7734 and JIS B 7736 for Brinell, Rockwell, Vickers and Knoop scales. Wilson originally developed the Rockwell testing process and standards. A “macro” test refers to a test where a load >1 kg is applied; similarly “micro” refers to a test where a load of ≤1 kg of force is applied. Additionally, some instruments are capable of conducting tests with loads as light as 0.01 g and are commonly referred to as ultralight or nanoindentation testers.

types of hardness tests

The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: . Smith, R.L.; Sandland, G.E. (1922). “An Accurate Method of Determining the Hardness of .

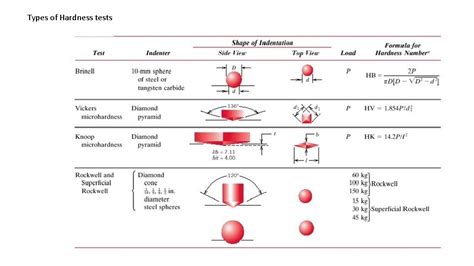

The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface. Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

Hardness reference blocks, also referred to as test plates, are used for indirect calibration methods and periodic daily inspection of hardness testing instruments. The use of high quality, consistent hardness reference blocks with minimal hardness deviation is essential to ensure the operational reliability of hardness testing machines. A numerical hardness value is assigned to the test material based on the results of the test. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a .

types of hardness testing methods

Minimum of two test blocks with at least one test block for each scale to be verified. At least two of the test blocks shall be from different hardness ranges. The difference between two blocks shall be a minimum of 100 points. The highest test force shall be verified on a block from the lower hardness range to product the largest indentation size.

Brinell and Rockwell Hardness Conversion Chart - These Conversion Tables presents data in the Rockwell A, B, C, D, E and F hardness range on the relationship among .Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. . the test may only loosen grains without testing individual mineral surfaces; thus, certain textures or aggregate forms may hinder or prevent a true hardness .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. . ASTM Hardness Standards Reference Guide Selecting a Hardness Tester Videos Articles Glossary - Hardness Testing .Vickers hardness test procedure Vickers hardness calculation Test force application Minimum distance test indentations Advantages and disadvantages Vickers hardness tester. To determine Vickers hardness in the standard and low-force range (200 gf - 120 kgf), the ASTM E92 standard is referenced instead.

types of hardness testers

The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to .The Brinell Hardness Test is one of the popular methods used to measure the hardness of metals. This method is used to inspect materials that have a rough surface, and other methods cannot be used. This article is an ASTM Brinell Hardness Standard Test Reference Guide.

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .Standard Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508; Superficial Rockwell Hardness Test Blocks - ASTM E-18 and ISO 6508; Brinell Hardness Test Blocks — ASTM E-10 and ISO 6506; Vickers and Knoop .

A hardness of 85 A would be harder than a material with 70 A. A tire tread has a hardness of 70 A while a leather belt can have a hardness of 85 A. 90 Shore A is a hardness measurement of “90” using the Shore A .

VICKERS AND KNOOP HARDNESS TEST - ASTM E384 E92 - ISO 6507 Index: Introduction Principle of Vickers hardness test . Vickers and Knoop Reference Guide. PRINCIPLE OF THE VICKERS HARDNESS TEST: The test consists of punching into the piece to be tested, using a determined force, a pyramid shaped indenter with a square base, having an angle of 136 .The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.After the test, the preliminary test force is removed and the indenter is removed from the test specimen. Types of Rockwell Scale Table-1 below gives the information on the type of indenter, the magnitude of the major load, and common applications for each of the hardness scales as per ASTM standard E18 (1984).We proudly introduce our two companies namely, “Fine Manufacturing Industries” and “Fine Hardness Testing Machines Pvt Ltd.” We Fine Manufacturing Industries is one of the group companies of Fine group of Industries. We manufacture Hardness Testing Blocks and Spares of Hardness Testing Machines, Indenters and Accessories etc. We received the NABL .

The Mohs Hardness Test is a simple procedure to gauge the scratch resistance of minerals. To perform the test, an examiner attempts to scratch the mineral in question with a reference mineral or material from the Mohs Scale. If the reference substance scratches the test specimen, the test mineral has a lower hardness rating.The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the . Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method. After the preliminary test force has been applied for a short time, the dial gauge is set to zero (reference level). The actual hardness value can then be determined. Figure: Rockwell hardness test procedure. The actual test load F 1 is applied in addition to the preload and the indetor penetrates the material with the total force F=F 0 +F1 .

hardness tester for thin material

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . The most frequently referenced hardness tests in material datasheets are Rockwell, Brinell, and Vickers, with Rockwell being the most prevalent due to its quick and straightforward process, especially in industrial settings. . Below is a quick reference chart comparing the different hardness test methods in terms of suitable materials .

hardness test procedure

hardness test pdf

WEBDan Taekema is CBC’s reporter covering Kingston, Ont. and the surrounding area. He’s worked in newsrooms in Chatham, Windsor, Hamilton, Toronto and Ottawa. You can .

hardness test reference|hardness test meaning